In this new era of vast technological advance, people no longer build machines solely by hand. True that people still have to supply raw materials and collect outputs, but the majority of the work has been taken over by machines. Computerized Numerical Control manufacturing, or CNC manufacturing, as it is commonly known as a process which helps create almost all of the industrial or agrarian machineries that are required in the modern days to help people ply the trades.

What Exactly is CNC Machining?

CNC machining is a software-based manufacturing system of machinery which are too tedious to assemble by hand. There is a pre-programmed set of commands in the compute in two different kind of loops – open loops and closed loops. Open loops are a uni-directional flow of commands from the source and motor. This is usually used in manufacturing of simpler and cheaper CNC parts because in an open loop, one can’t perform error correction as there is no way to receive instantaneous feedback from the motor. This is one of the best pros about having a CNC manufacturing plant.

Why Choose CNC Machining Over Other Forms of Machine Building?

The primary and most important reason to choose CNC machining over any other form of machining is the automaticity of the entire process. The command set you enter is going to determine the machine that you build and the CNC parts you require. And through all these you don’t have to drearily compose and compound each piece, one by one. The easy transportation facilities, along with precise machine production makes CNC machining more profitable over any other form of machine manufacturing. Hence, with the help of CNC machining and AutoCAD designs, you can go for low-cost commercial effectiveness, with high quality production. The cost will be low, yet the productivity will be high.

What Are the Various Types of CNC Machinery Available in The Market?

- CNC mills: Easily one of the most sophisticated system of machinery, the CNC mill machines are usually tasked with running along the X, Y and Z axes.

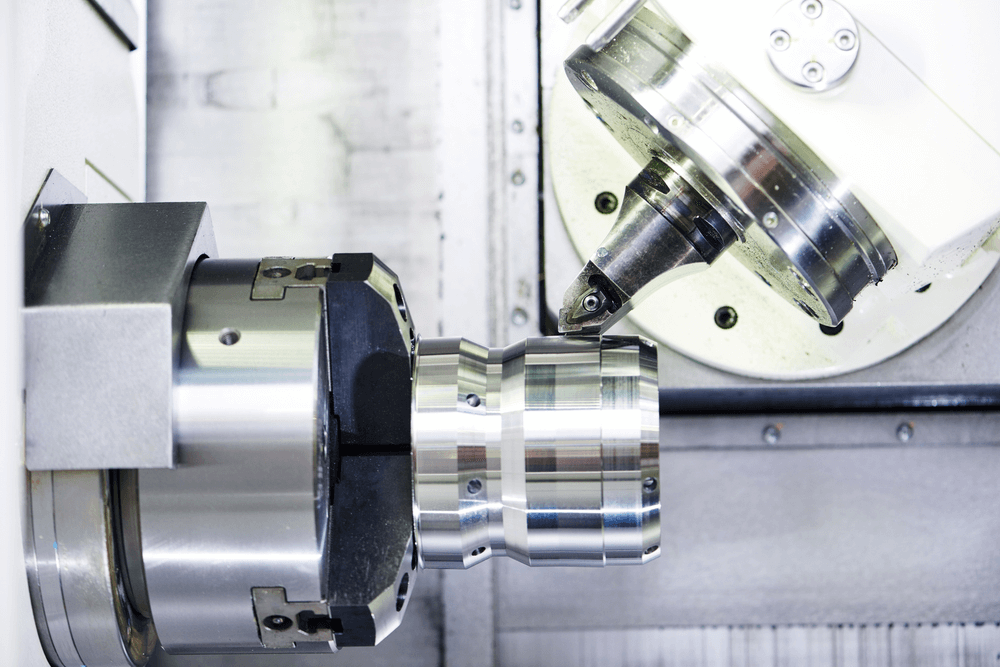

- Lathe machines: Complex designs created by the CNC lathe are virtually impossible to create manually as the CNC technology handles the job with high precision and velocity. Like the CNC Mills, it can be run by unique proprietary codes or the G-codes. But unlike CNC Mills, the CNC lathes run along only 2 dimensions, X and Y.

- Plasma cutters: This is prepared from a plasma torch. One can easily cut metal with these cutters, but other handy stuff can also be cut with the plasma cutters which offer a variety of uses for the device.

- Water jet cutters: One of the most cost-effective cutters available in the market is the water jet cutter. This device is a prime example of CNC machining as water from the pipeline is forced and made to flow at an extreme velocity from the mouth to create enough pressure to cut through even steel.

Is CNC Machining the Future of The Sector?

At the moment it looks like CNC machining is going to be one of the cutting-edge technologies as workers say bye to hazardous and unhealthy working conditions as mechanics. CNC machining is also used for a variety of other purposes like – turret punchers, 3D printers, embroidery machines and so on and so forth. In almost every sector of our life, CNC machining has taken over, and the primary reason of doing so is the increased efficiency of the machines made through the CNC machining processes. You can now choose auto adjustment parts, spindle motors and linear adjustment parts that can help you to produce more, and lead to less labor cost for all your commercial requirements.